Our services

in the fields of Biopharmaceuticals

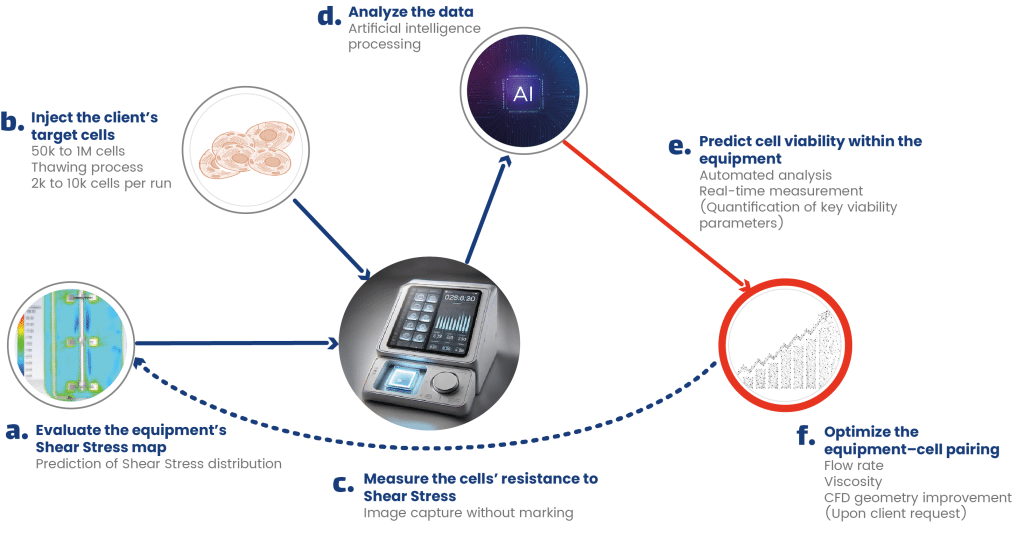

The CellXplore™ service pipeline has been designed to mirror real bioprocess conditions while delivering highly valuable data.

We begin with fluidic modeling of your equipment using CFD tools, allowing us to simulate flow behavior and predict high-shear zones.

Next, we prepare your cells of interest—typically between 50,000 to 1 million. After thawing, a sample of 2,000 to 10,000 cells is used per run, enabling efficient screening without excessive resource use. Your cells are then exposed to real flow conditions in a controlled setup.

Moreover, an integrated AI engine process this image data in real time, classifying each cell by its physiological state and generating a report on viability distribution within the flow system. Finally, we assist you in optimizing your equipment or process, adjusting flow velocity, viscosity, or even the geometry of your design based on predictive insights—ensuring the best possible cell–equipment compatibility.

The 3 key phases of the process

How does it work?